Power generation from waste heat at Bilstein GmbH & Co. KG

The cold rolling mill BILSTEIN has built a new state-of-the-art bell-type annealer which can be operated in a highly energy-efficient manner thanks to the innovative heat recovery concept.

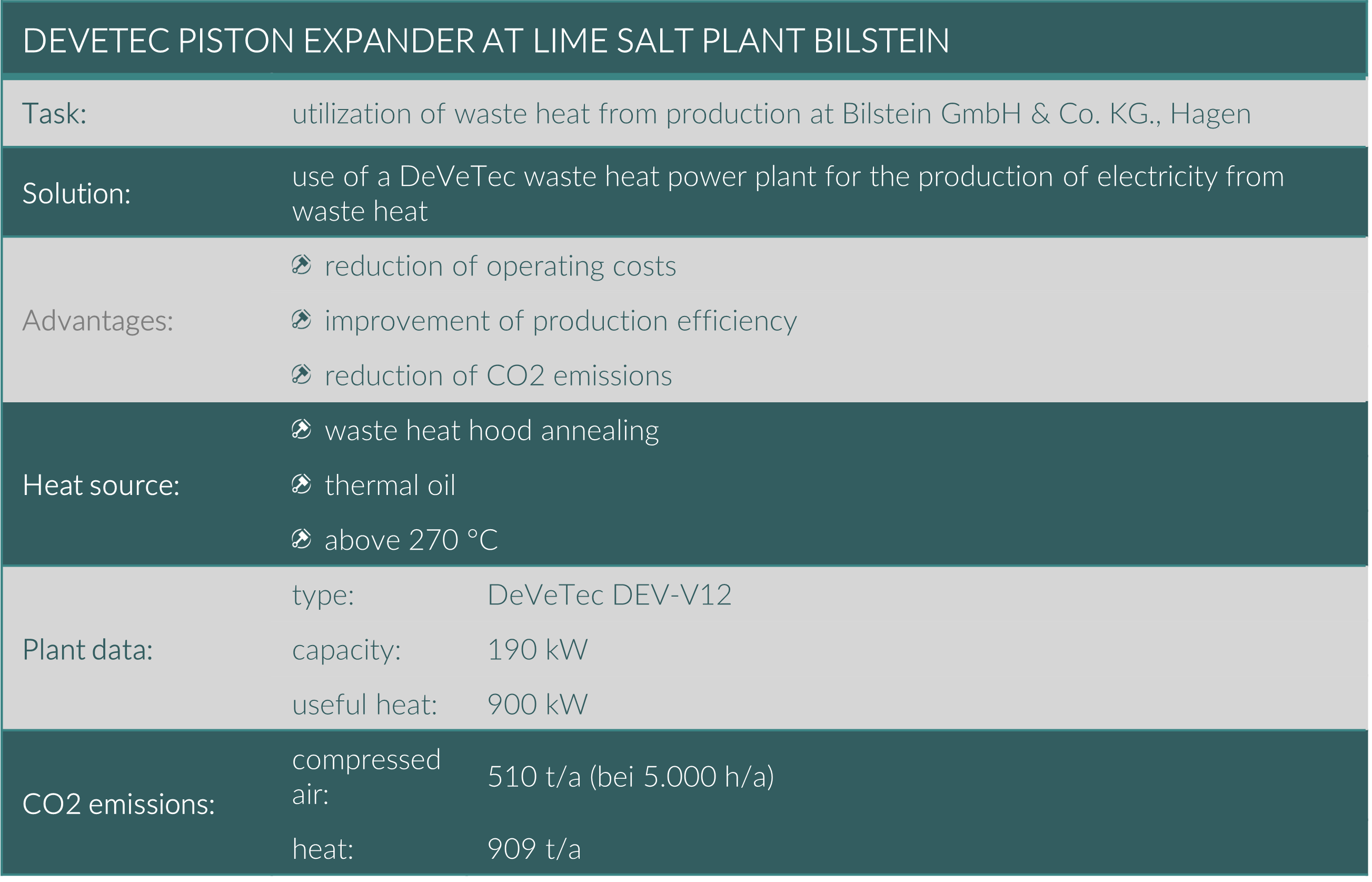

During the controlled cooling of the coils, waste heat is generated which is transferred to the ORC medium ethanol of the waste heat power plant via a thermal oil circuit. The DeVeTec waste heat power plant generates from waste heat up to 190 kW of electricity and up to 900 kW of heat:

The system was funded by the German Federal Ministry for the Environment as part of the Environmental Innovation Program.