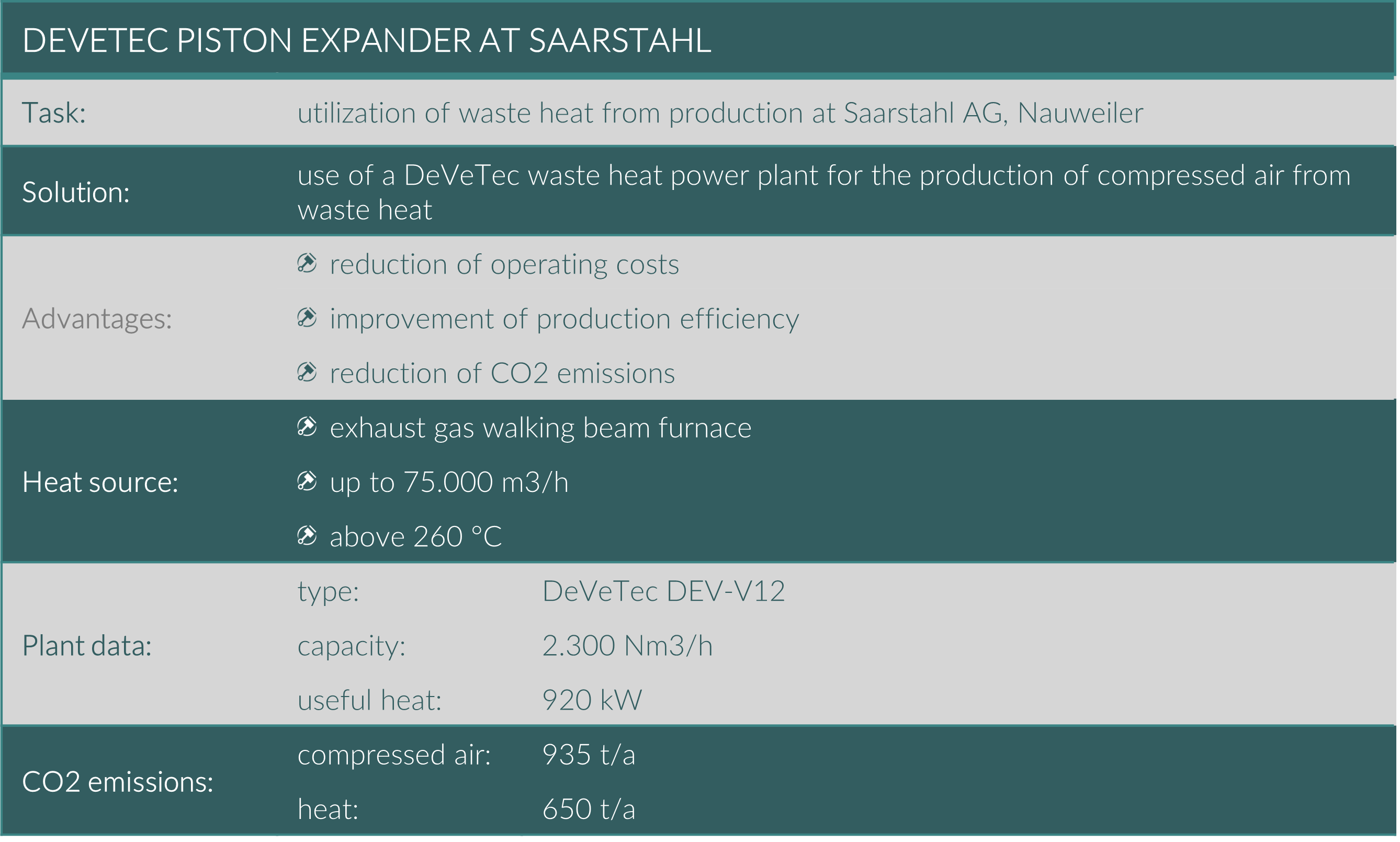

Compressed air production from waste heat at Saarstahl AG

In Völklingen, Saarstahl AG uses a waste heat power plant to harness the waste heat from a walking beam furnace. As there is a high demand for compressed air in the plant, the unique DeVeTec technology is used, where the air compressor is directly driven by the DeVeTec piston expander.

The steel slabs produced in the steel mill have to be heated to pprox.. 900°C before forming. The energy required for this is generated by burning natural gas or converter gas. The energy from the waste gases produced in the process is used in the waste heat power plant:

The plant was supported by the energy efficiency program "Waste Heat".